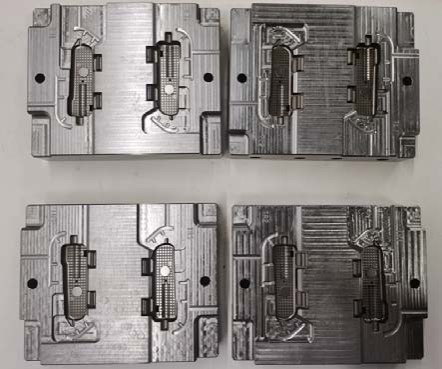

BOSCH Tooling Cavity

Brand Name:Hamsan

Mold Base:LKM;HASCO;DME,etc

Mold Material:SKD61

Tolerance:+/-0.002mm

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Wooden case

Delivery Time:18 days since confirm

Products Details

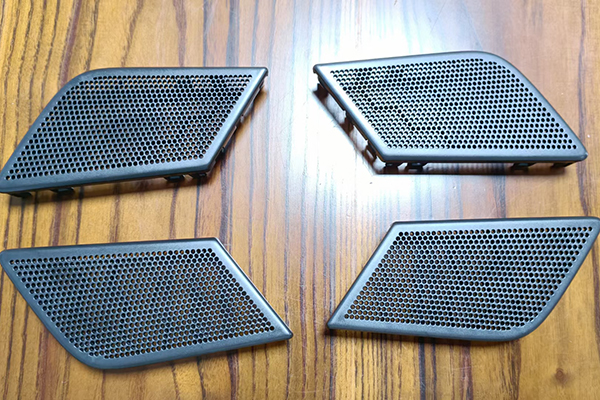

ABS Multi Cavity Mold Core, PP Single Cavity Mold Core, Automotive Plastic Moulding Components

Hamsan Tooling prides itself in our In-House Design and Manufacturing. We employ highly skilled and professional operators for our drilling, CNC, EDM, Proprietary Mirror EDM, and Mould Polishing machines.

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Product Description:

Product name: BOSCH tooling cavity

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm

2. Day shift and night shift.

3.22 years of experience in the mold industry. We have rich experience in Experience of cooperating with mold factory

4. 30 set CNC machine, Can handle more than 10 sets of mold accessories at the same time every month.

5. 5-axis CNC machine, can handle big mold slider and mold base.

Hamsan Tooling prides itself in our In-House Design and Manufacturing. We employ highly skilled and professional operators for our drilling, CNC, EDM, Proprietary Mirror EDM, and Mould Polishing machines.

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Product Description:

Product name: BOSCH tooling cavity

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm

Our advantages:

1. Whole set mold components solution, which means, we could help you process all components on a mold, such as a mold base, mold core, sliders, standard parts...etc2. Day shift and night shift.

3.22 years of experience in the mold industry. We have rich experience in Experience of cooperating with mold factory

4. 30 set CNC machine, Can handle more than 10 sets of mold accessories at the same time every month.

5. 5-axis CNC machine, can handle big mold slider and mold base.